Using drones to measure stockpiles is quickly becoming a go-to surveying workflow for earthwork sites around the world.

Using drones to calculate stockpile measurements makes it easy to compare your current stockpile volumes to previous surveys and track site progress. You can also compare stockpile surveys to a final grade design file to calculate how much material you still need to add or remove.

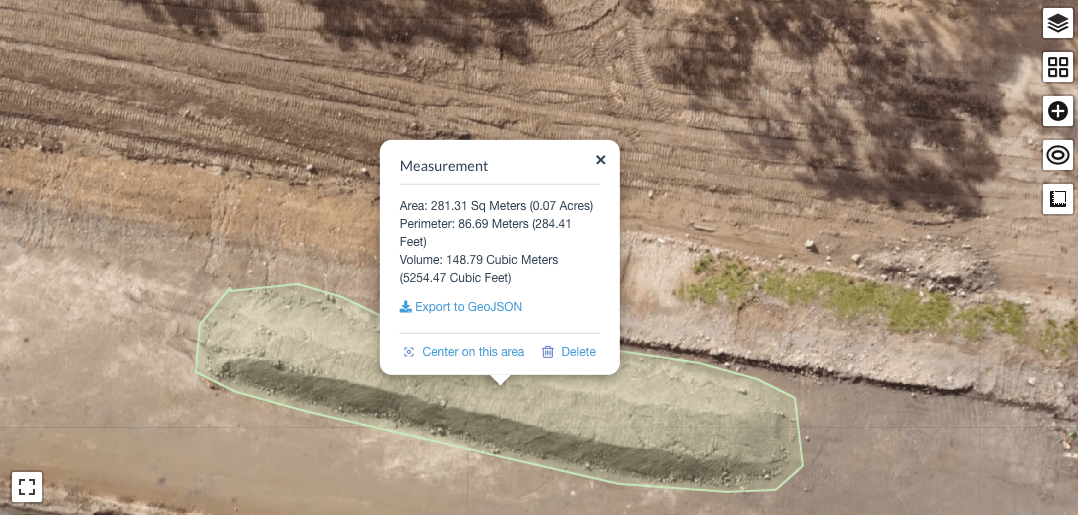

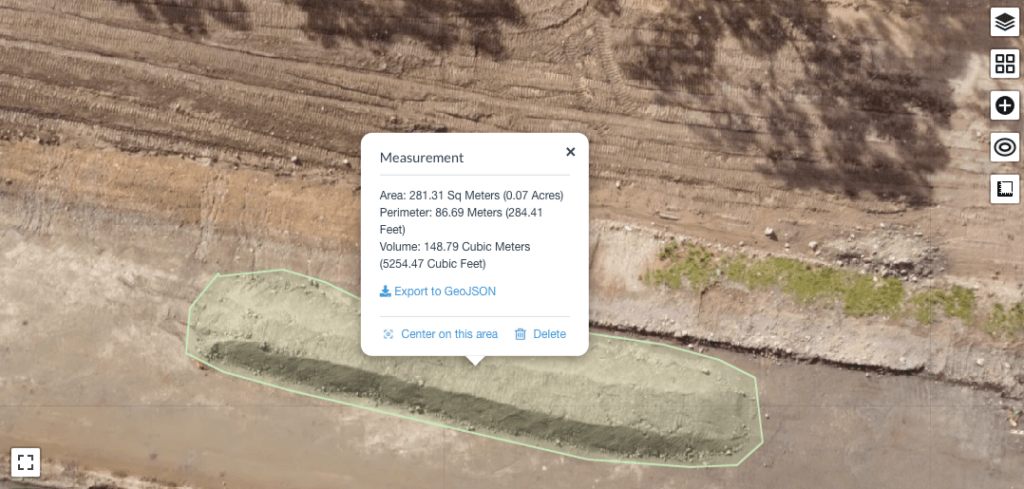

With geo-referenced images captured by a drone flying above your worksite, you can use photogrammetry to generate a 3D map of your site with measurements accurate to 1/10ft (3cm). Drone survey visualisation platforms, leverage that accuracy to take a variety of measurements, including stockpile volumes.

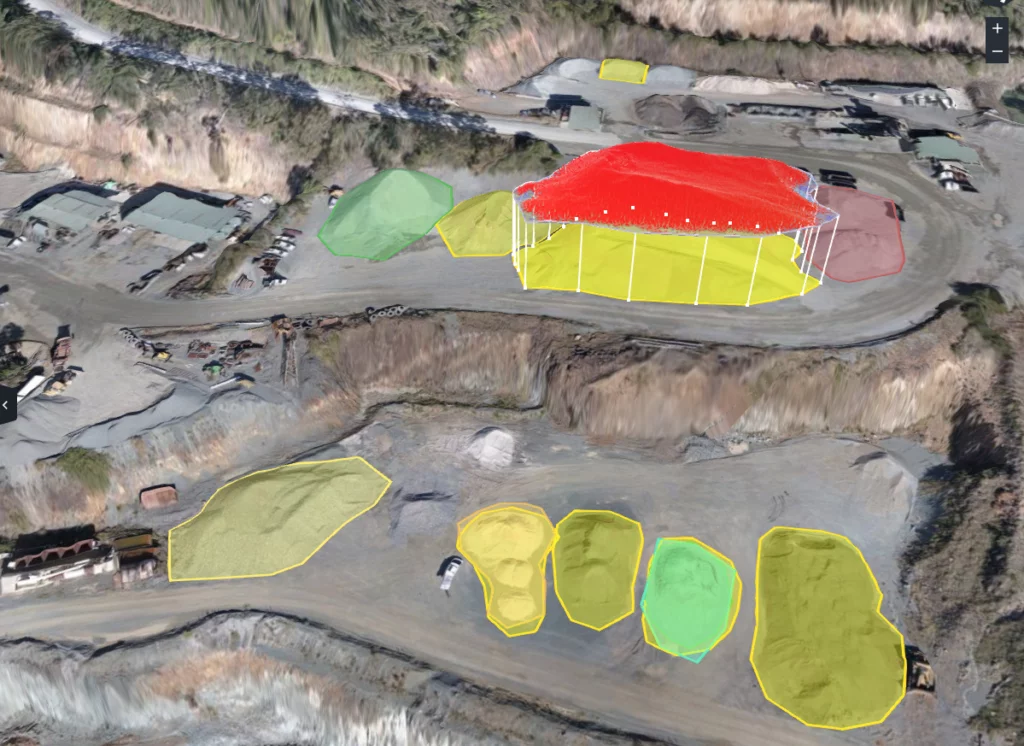

For professionals in the mining and aggregates industries, stockpile inventory management is one of the primary use cases for drone surveying. Construction sites also use drones to survey their sites more quickly. The 3D maps generated from those flights collect actionable data, including stockpile volume calculations.

Why accurate stockpile volume measurements matter

Mine and quarry managers spend much of their time answering questions—or trying to answer questions—about quantities. How much is sitting in the stockyard right now? How much is going in the crusher or mill? What do you still need to extract? How much have you moved since last Thursday? What was its true value, and did you sell it for the right price?

When you have accurate site surveys at your fingertips—and thus full oversight of your stockpile inventory—finding the answers you need gets a whole lot simpler. Drone surveying workflows provide dependable, highly accurate stockpile measurements. And you can measure progress as frequently as you want to fly. This influx of stockpile inventory data enables teams to tighten up worksite operations, which can include everything from financial forecasting and supply-chain management to accurate reconciliation.

Stockpiles in Bins

Where stockpiles are contained within bins such as at landscaping suppliers, concrete batch plants and many other locations, inexperienced drone operators can provide you with very inaccurate volume reports. We’ve developed and tested our work flow to ensure it accounts for the missing “toe” of the pile without accounting for the walls of the bin. This process takes a bit more effort but it’s worth it.

If you need very precise stockpile measurements, we can provide cm level accuracy, utilising ground control points established with GNSS/RTK and NTRIP.