Case study 1 – Using drone-acquired imagery to manage a high biomass crop

Bradley Donald, B&W Moree, Elders Rural Services, NSW

In 2016, a paddock of Commander barley near Moree, NSW was assessed as having high yield potential. Nevertheless at growth stage 30, areas of crop within the paddock were seen starting to lodge. Applying a growth regulator to the crop was a good option to reduce the lodging, but applying the full rate to the entire crop was considered unwarranted and expensive at $30/ha.

Agronomist Brad Donald, estimated that applying a growth regulant to prevent lodging in the high crop biomass areas could potentially increase yields by 0.5 t/ha and, with barley worth $200/t, this would generate an additional $100/ha.

Persistent cloud cover at the time prevented the use of satellite NDVI imagery. Instead, Brad generated an approximation NDVI map of the paddock using 700 images collected using a modified Canon S100 camera with a near Infrared (NIR)/blue/green lens that filters out the NIR wavelengths, mounted on an AgEagle fixed wing drone. The images were stitched together using offline Agisoft Photoscan software then georeferenced to fit the coordinates of the 128 ha paddock. Georeferencing is the process of assigning real-world coordinates to each pixel of the digital image. These coordinates are often obtained by collecting coordinates with a GPS device for few easily identifiable features in the image. Using these sample coordinates, or ground control points (GCPs), the image is warped to fit the area being surveyed.

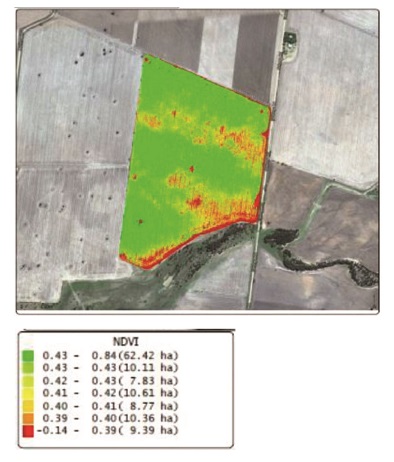

SMS Advanced Mapping software was then used to estimate the NDVI of each pixel in the composite image, highlighting the high biomass zones (Figure 1), which were the areas of the crop at risk of lodging and amounted to 72 ha. Field inspection confirmed that the areas of highest biomass in the paddock were also identified on the map as areas with NDVI ≥ 0.43.

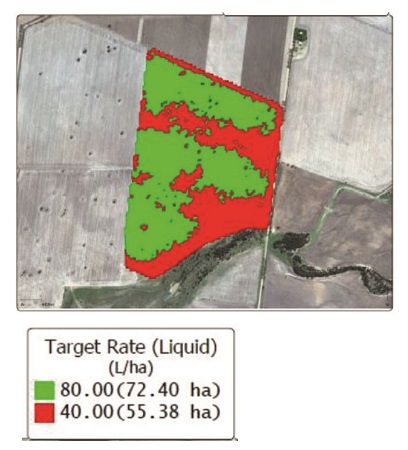

From the drone image, Brad produced the variable rate (VR) prescription spray map (Figure 2), which was loaded into the spray unit controller and used to apply the growth regulant. By varying the water rate of the spray unit, the high biomass zones (green) were sprayed at the full rate of Moddus Evo® (400 mL/ha) with a water volume of 80 L/ha, and the remainder of the paddock (red) received half the rate by lowering the water volume to 40 L/ha.

Figure 1. NDVI-approximation map generated from 700 images taken with a drone-mounted camera using an NIR/B/G lens that filters out the NIR wavelengths to show variability in crop biomass.

Figure 2. Spray application map showing high (80 L/ha, green) and low (40 L/ha, red) application rate zones.

The result was a reduction in cost of the product and increased yield due to a reduction of lodging. Additional un-costed, but significant, benefits in this case from the application of growth regulant included ease of harvest and improved stubble management for the next season.

The advantages of using a drone in this instance were:

Rapid capture of images, which were unavailable from other sources due to cloud cover.

Timely processing of images and critical decision-making.

Making observations at a time when the paddock was untrafficable due to wet conditions.

Figure 1. This paddock of Commander barley near Moree was sprayed with two different rates of growth regulant Moddus Evo to avoid yield losses to lodging. A strip down the centre of the paddock was left unsprayed and clearly stands out in this photo, showing a much greater level of crop lodging than the rest of the paddock.

Case study 2 – Using a drone to manage herbicide resistant weed patches

Mark Branson, Branson Farms, Stockport, SA

Crop and livestock farmer, Mark Branson has added a drone to his precision agriculture toolbox, specifically targeting patches of herbicide resistant weeds. Mark has chosen to use a DJI Phantom 4 (4-rotor / quadcopter) with its standard high resolution digital camera to monitor weeds during the crop season.

Early in the crop growth Mark is able to assess the weed pressure in a paddock using images that show individual plants that are 3 cm in diameter or wider, growing between the crop rows. Mark can use these images to generate a VRT map so he can target the surviving weeds with more expensive herbicides.

Once the canopy closes over, Mark uses the drone to spot weeds that are growing above the crop. Wild oats is of particular concern and seedheads can be seen very clearly in the drone images. Depending on the area of infestation, Mark will either bale the affected area for hay or consider spraying out larger areas of the crop as a last resort to prevent the weeds from setting seed.

Mark flies the drone himself, following a flight path that provides even coverage of the paddock. He then uploads the images to a cloud-based service provider. The images are ‘stitched’ together and a digital data map is returned to Mark, which he can upload to his tractor’s GPS monitor.

The same maps can then be used the following season to increase the seeding rate in the weedy areas to increase early crop competition to apply pressure to any new germinations of weeds.

Rather than analysing the images himself, Mark has purchased a subscription to ‘Drone Deploy’ services. This subscription service provides more accurate maps than the free service and saves Mark a considerable amount of time.

To use the cloud-based service requires access to NBN wireless or equivalent internet upload speeds.

In addition to using the drone to manage weeds, Mark has also found value in spotting mistakes or misses after spreading urea or seeding. Early detection means there is more opportunity to correct any mistakes.

Source: Society of Precision Agriculture Australia (SPAA)

This case study was supported by SPAA through funding from the South Australian Grain Industry Trust Fund as part of project SPAA118 – Conversations with Farmers: Agricultural Practice Change with the “PA-Early Adopters”

Original Produced by AgCommunicators P/L and Lightning Designs

More case studies available from SPAA website: www.spaa.com.au

We’re always pleased to provide you with a quote but bear in mind that before we accept any job and sometimes before we can provide an appropriate quote, we may need to ask you some questions. There are many regulations that apply to the operation of RPAS (remotely piloted aircraft systems). we’re required by CASA to ensure that we at all times operate in a manner that is safe and legal.